Halliburton has launched the next-generationTuring electro-hydraulic control system, with bidirectional choking and built-in position sensors for fast and accurate flow control

Part of Halliburton’s of SmartWell intelligent completions technology, this system sets a new standard in reservoir flow control suitable for all completion applications, improving recovery and reducing well count.

The Turing electro-hydraulic control system facilitates fast zonal optimisation through integrated position sensors that help operators manage well performance with speed, precision, and confidence. Its simplified, flexible design reduces rig time, operational risk, and production delays to deliver measurable value to our customers.

Operators can remotely and selectively adjust zonal ICV positions in seconds. Built-in high-resolution sensors increase fidelity and expand choke position options. Fast, precise bidirectional control of the ICVs enables flow control from or into each zone without closing the ICV. This capability supports routine, active well optimisation and supports the adoption of fully automated, data-driven optimisation technology.

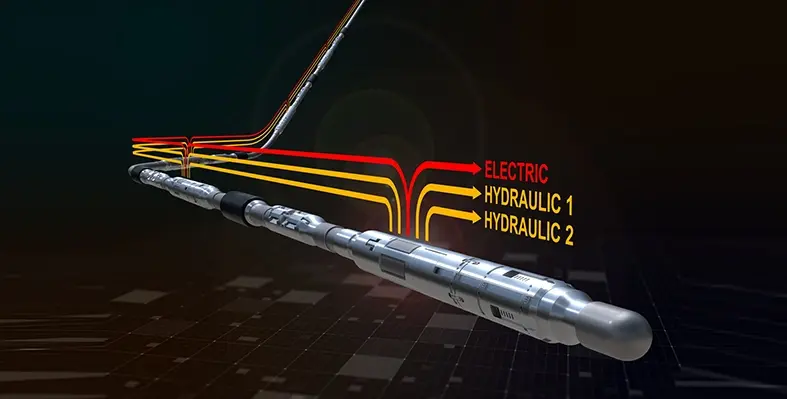

Paired with the Clariti digital reservoir management suite, the Turing electro-hydraulic control system provides customers with added insights and real-time advice on opportunities for well production and field optimisation. The system can manage up to 12 zones with three control lines, two hydraulic and one single-wire tubing-encapsulated conductor (TEC). The TEC line communicates with downhole sensors through the DataSphere permanent monitoring suite to eliminate additional lines and reduce subsea infrastructure costs.

“As the pioneer of SmartWell intelligent completions, Halliburton’s advancements in this technology strengthen our industry leadership. Our new Turing electro-hydraulic control system builds on that legacy. It empowers our customers to improve recovery, manage subsurface uncertainty, and achieve lower costs with greater operational efficiency,” said Maxime Coffin, vice president, Halliburton Completion Tools